If you want to invest in a 3D printer but you’re unsure about which model is best for you or if you want to learn more about how they work, you’ve come to the right place. In this article, we present a complete guide to 3D printing so that you understand the basics.

How does 3D printing work?

3D printers take a digital 3D file and then transform it into a tangible 3D object. The way that 3D printing does this is by using a specific manufacturing process called additive manufacturing. The traditional alternatives to 3D printing are subtractive manufacturing techniques like carving or milling however they’re much more time consuming, labour intensive, and cost heavy.

While each 3D printer is unique, they all need the following to work:

Digital file

A digital file tells a 3D printer how to create a three-dimensional object. This digital file divides up the object into individual layers describing each of these layers in real detail. All a user needs to do is upload a finished digital file into a 3D printer and then that printer does the rest.

There are various programs designers use in creating digital files, perhaps the best known of which is Tinkercad, recommended for beginners in 3D printing.

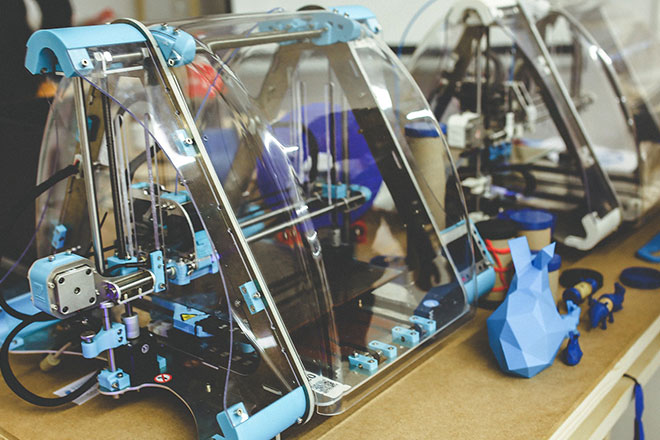

Printing machine

For the machine to accurately copy the layers described by the digital file, the machine needs enough free, clean space to construct the object. Therefore, most 3D printers have a box or vat in which the object is produced.

A 3D printer typically uses lasers or nozzles to lay down the material and it then moulds an individual layer’s material to the correct shape, finally binding it to the layer below.

Printing material

The majority of 3D printed objects are made with one material however that single material itself can be made from several substances. ABS plastic is one of the most popular choices for 3D printing because it gives users many different colour options.

Depending on the model of 3D printer you have, you can use metals, synthetic sandstone, nylon, resins, or hybrid elements made up of plastics and various other materials to create your desired object.

What types of 3D printing are there?

Although 3D printing techniques have been available for decades, the demand for them increased after Fusion Deposition Modelling (FDM) became available to the wider public (more on that later).

FDM is, to many, the most consumer-friendly way of getting into 3D printing. It’s cheap and it’s relatively easy to use. All you need to get started is a box, nozzle, and compatible software. The printers themselves come in various different sizes meaning that, for users wanting to print really large objects in 3D, all they need to do is to buy the right-sized machine for their needs.

The three other most popular types of 3D printers are:

Stereolithography (SLA)

Stereolithography was created in the 1980s and it works by beaming a laser at liquid resin to first shape the resin and then to make it harden instantaneously.

The object is then pulled out of the vat of liquid resin by each individual layer. It’s a much more complicated printing process than FDM however what it ends up producing is at a much finer level of detail.

Selective Laser Sintering (SLS)

Selective Laser Sintering printers use powders containing specific properties like polyimides and thermoplastic elastomers.

The SLS laser fuses these powders at the correct position and then into layers to create the desired three-dimensional object. This printing process creates objects that are widely noted for being very durable.

SLS printers are generally used to mass-produce functional parts or prototypes.

Metal printing

Two established techniques successfully used in metal printing are selective laser melting and electron beam melting. Both of these methods work by very slowly lowering the platform onto which an object is being printed.

As this is happening, powdered metal is added in layers and then melted using an incredibly-precise guided laser. This type of printing must take place within strictly controlled environments meaning that it’s rarely used outside of the industrial manufacturing sector.

Jetting processes

The jetting process works by spraying a reactive polymer to an object’s base. After this, a UV light is projected to harden the polymer and this process is then repeated to the following layers until the whole object is created.

However you should note that some versions of jetting use powdered materials and layers of glue alongside the UV light technique.

While jetting is most similar to inkjet printing, the biggest difference between the two is that jetting uses advanced polymers with their own unique properties. This type of printing can create highly detailed objects, but the technique isn’t typically outside industrial settings.

What can I use 3D printing for?

Today, 3D printing is being used by companies across many different lines of business for a whole host of reasons. It’s cheaper than other methods of mass production, it’s faster for creating prototype models, and its advocates claim that it improves rates of commercial efficiency.

So what industries that are already using 3D printing?

Healthcare

Disposable healthcare items, such as sample cups, are often created by 3D printing systems. 3D printing has also greatly benefited the world of prosthetics. A prosthetic limb, for example, can be solely customised for an individual’s unique needs and desired uses.

Shoes

There has been a rise in companies which solely manufacture 3D printed shoes in response to a growing appetite for unique footwear from the consumer market. 3D printed shoes and trainers are created on demand and they can be customised specifically to individual tastes.

Feetz is a company that has used 3D printing to create sustainable, custom fit shoes. The business has been so successful that they now hold the achievement of being the “world’s first runway collection of 3D printed shoes at FashionNXT”.

Houses

Housing manufacturer, Apis Ctor, has developed an entire house that can be printed in 24 hours and it comes fully painted too.

Custom ordering

You can now purchase a 3D printed object from the comfort of your own home. All you need to do is specify the object you want creating and the material it should be made from. Then the printing company offering the service does the rest once you’ve placed your order online.

Set design

3D printing isn’t just a cheaper and faster option for manufacturing commercial products – it’s also cost- and time-effective for those creating theatre props.

Instead of dedicating many hours to creating specific props needed for a show, many theatre productions now use machines with which they can draw, program and print ready-to-use objects and sets.